Expanded Polystyrene Insulation

Boards (EPS)

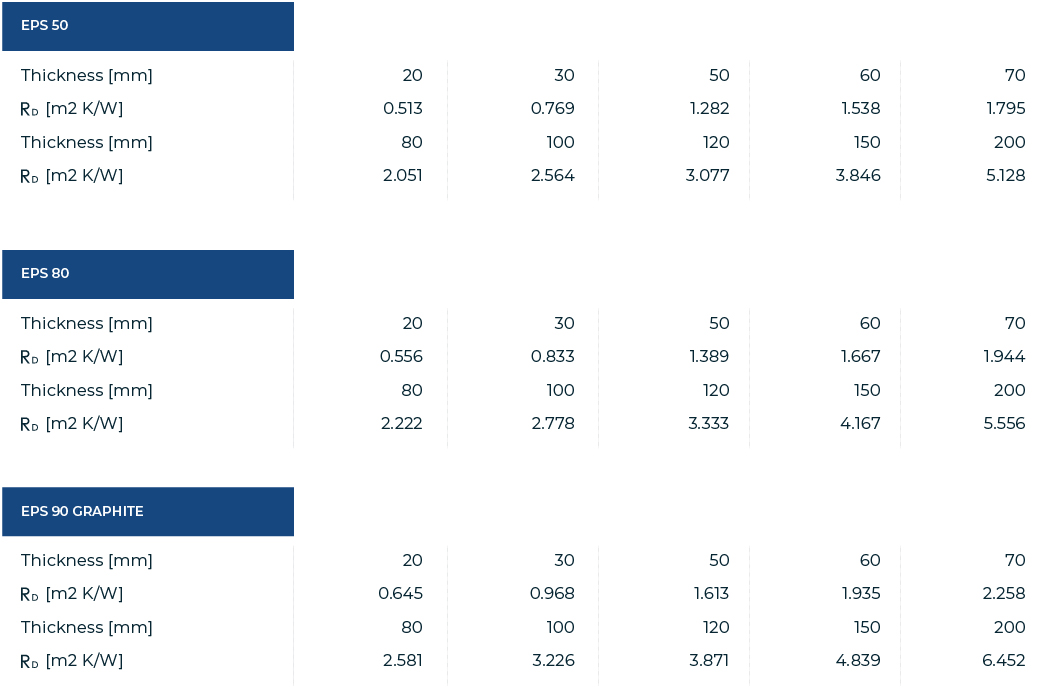

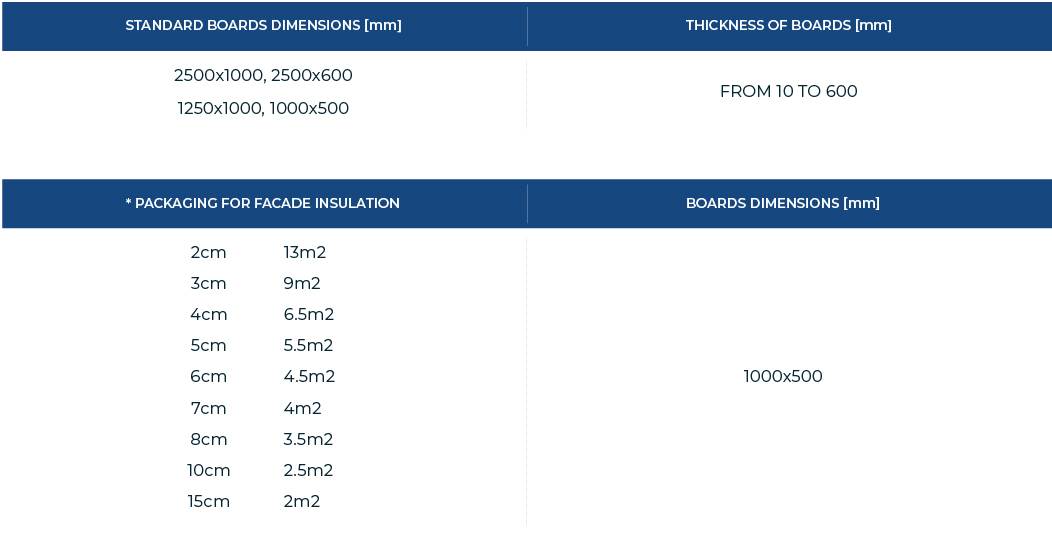

EPS Polystyrene boards are available in various densities and thickness. They are produced according to standard EN13163 and under continuous laboratory tests.

The application of expanded polystyrene as insulation material for buildings and homes is one of the best solutions for saving energy and protecting the environment.

Benefits:

- Excellent insulation properties

- High mechanical resistance

- Low moisture absorption

- Non-flammable – Euroclasse E

- Biologically harmless and 100% recyclable

- Lowest cost per unit of R-value compared to all other foam insulation products

Applications – Uses of EPS:

• As a heat insulating material in outer walls of houses.

• In walls and roofs of prefabricated houses and for indoor partitioning.

• In ceilings and roofs of buildings

• In the inner walls of refrigerators and cool rooms

• For foundation insulation and avoiding subsidence

• As an insulating and protective material for packaging

• In joints and shoring walls for contractions / dilations and for protection.

• For renovations and decorations

Graphite Polystyrene for External Wall Insulation

Graphite polystyrene is a new generation thermal insulation material. The graphite polystyrene is absorbing and reflecting heat radiation and improving the already very good thermal conductivity of expanded polystyrene.

Compared with white EPS, the graphite polystyrene can reach the same insulating effect, requiring considerably less material.

For additional information and manufacturer declaration of performance: EPS90 Graphite (Click for more)